We aim to eliminate all the unclearness in your mind about 'fiber laser marking machine', within this heading. As those who take place in the sector know and those who want to take a new step in the sector will learn from now on, "fiber laser marking machine" takes place in more than one field. We encounter this machine in many fields such as plastic materials taking place in our daily shopping life, defense industry, medical sector, automotive industry, shipbuilding industry and all of its manufacturing lines, mobile phones, smart watches, tablets, computers, briefly all electric-electronic industries, jewelery and design sectors and many other fields. We have answered all questions about this sector together with our expert team in order to be a guide for new entrants and to convey important information about fiber laser marking machine for either people who have just entered this business or who have experience in this business.

What is Fiber Laser Marking?

Fiber laser is a type of laser that contains rare elements in nature, it can leave permanent marks and marks on the products you want to mark with a computer-controlled system with the laser light coming out of the power source during the marking process. Thanks to fiber laser marking, non-contact, more precise, environmentally friendly, high-speed, reliable and low-cost, as well as adjustable process for different materials. These different materials provide flexibility to meet the needs of the industries. We can cite structural steels, stainless steels, plastic, gold, silver, brass, copper, echoed and painted surfaces, composites, titanium, ceramics, silicon, leather, iron and different aluminum grades as examples. In addition to these, the durability of the signs is permanent and high contrast. They can withstand temperatures, abrasions and even acids, in addition to being colorfast and water resistant, once again reveals the difference of the fiber laser system. These traces and mark samples can be reproduced as expiry dates on plastic bottles of water we buy from markets, QR codes, manufacturer's logo or brand name, emblem, souvenir printing, prints on jewelry, markings on metal used in the manufacturing industry. In short, fiber laser marking makes use of rare elements in nature, leaving permanent marks on the materials with the beam emitted from the power source.

Will Laser Marking Damage The Relevant Product?

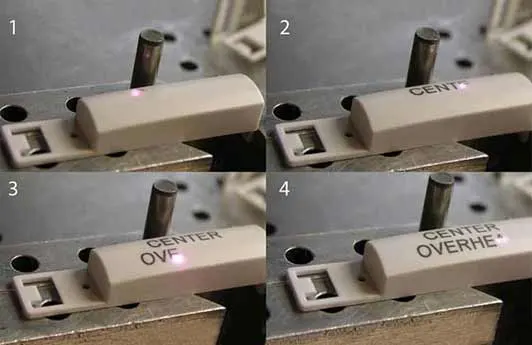

First of all, it should be noted that the marking process was first made by printing methods with ink in the pad printing on the products. We can give serigraphy as an example. These methods were damaging your product and reducing their quality. Laser technology, which emerged with the advancing technology, replaced the more traditional methods. The operations performed with this laser technology are performed both faster and more securely than before. In addition, laser marking, which minimizes or even completely removes the error margin in your products, provides you with the opportunity to achieve more efficient results. Fiber laser marking machine consists of permanent marks you leave on the products as per your request. This method of leaving the mark only at your request, thanks to this developing technology, is applied only to the regions you want, and this method reveals its difference with the traditional method.

What is Annealing and Color Marking?

Annealing laser process and color marking is a type of process. The traditional methods mentioned in the previous question have been abandoned and laser technology has been used for both types of operations. The annealing laser process is a type of laser used only for metals. However, it is useful to expand the definition a little here. Laser annealing can be applied on metals that are exposed to oxygen and heat that exhibit discoloration. While making the explanation, we used the term laser annealing deliberately, and if we remind again the reason for this, it is to point out that traditional methods have been abandoned and new technology is now being used. With the laser annealing process, undamaged surfaces can be created and this technique can be used in the production of sensitive devices such as medical devices. In addition, very thin wide lines can be created with this system. As for color marking, with this system, which can also be referred to as "Color Laser Marking", color marking can be made on the marked object with certain codes entered in the computer. Due to the increasing demand for color marking processes in the market, manufacturers are working to produce lasers operating at different wavelengths. Thanks to different wavelengths, it is aimed to create different colors and to make color variation with laser in the marking process. In this type of process, colored marks can be left on the stainless steel with Mopa Fiber Laser, or if we are more descriptive, it can leave a mark.

What is Laser Annealing, How Is It Applied?

The annealing laser process is a very special method, it is a district heating process that can change the color of the heated product in relation to the temperature of the heat. Nothing is removed from the surface of the heated product during annealing. The continuous heat of the laser over a given area creates an oxidation reaction process that leaves a permanent mark. With this system, which is the sign of heat annealing, it leaves us a permanent and readable mark (trace) after the processes of heating and cooling the color on the metal surface. Annealing laser processes are mostly done with metals and leave the applied surface smooth and clean after the process. During annealing, low heat is applied in order to protect the health of the product. Therefore, out-of-focus lasers are used in this area. Oxidation; It is a type of etching that causes a color change on the surface of the metal where the reaction occurs. However, it is worth noting that the surface is not damaged in these processes. It is also possible to obtain different colors depending on the temperature. If the metal is heated up to 200°C, the marking process loses its effect and disappears.

What Are Other Operations Performed With The Laser Machine?

Marking leaves a permanent and controllable precision mark on the surface of the material.

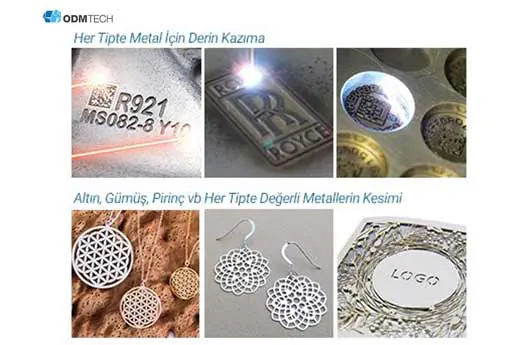

Laser engraving, unlike marking, is preferred in jewelry production such as gold and silver, as well as in molding and metal processing industries to process patterns and texts on molds.

Although engraving is sometimes used synonymously in both terms, there is an important difference to highlight. Laser marking only leaves a permanent and controllable precision mark on the surface of the material. laser engraving, on the other hand, involves a permanent depth in the material. It is similar to engraving in form.

Cutting is the process of cutting the material of certain thicknesses in a computer-controlled shape.

Carbonization is a necessary method to leave black text marks on the surface of materials such as Fiber Laser, Stainless Steel, Sheet and so on.

What is Day and Night Marking?

We can mark day and night with the fiber laser marking machine. This type of marking is more common in the automotive and electronics industry. Day and night laser marking technology is a system that works using a concentrated laser beam until it reveals the colored lacquer layers, especially in the automotive and electronics sector, the color the manufacturer wants. Transparent surface materials are illuminated in the targeted direction. Thanks to this application, the products provide a level of illumination that can be called perfect day or night. We use the benefits of this technology at every moment when our daily life meets technology. In addition, thanks to this technology, manufacturers can use it to illuminate smaller areas, thus providing a great advantage in controlling the layout and aesthetics (vehicle dashboard, car, etc.). It gives freedom to producers in this regard, so to speak.

Which Materials Can Be Laser Marked?

As is known, we can engrave most metals thanks to Fiber Laser marking machines. However, this does not mean that these machines only mark metals. They can mark plastics (pet bottles), ceramics (marbles), glass and silicon with laser marking method. In addition, depending on the material used in the building, graphite, composites, rubber and LEDs can be marked with any color or black. In addition, we can use laser marking when writing precious metals such as rubies, sapphires or even diamonds with great value.